In today’s fast-paced manufacturing world, precision, consistency, and speed are no longer luxuries—they’re necessities. Among the many advanced fabrication processes available, CNC Routing Services stand out as a cornerstone of modern production. From creating detailed prototypes to handling large-scale industrial projects, CNC routing has transformed the way industries approach cutting, shaping, and customizing materials.

Companies across woodworking, plastics, composites, and metals rely heavily on these services to achieve results that traditional methods simply cannot match. With the growing need for accuracy and repeatability, businesses increasingly turn to a trusted CNC Routing Company to streamline their operations.

What Makes CNC Routing Services Essential?

The Evolution of Routing Technology

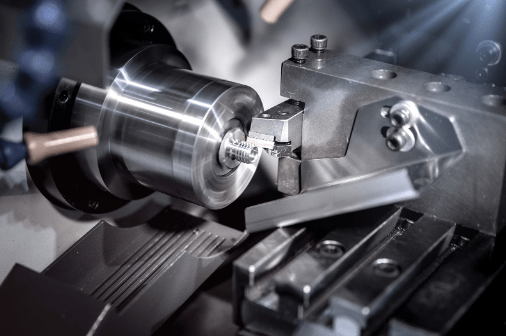

Routing has been around for decades, but the introduction of computer numerical control (CNC) revolutionized the process. Instead of relying on manual tools and the steady hands of operators, machines now operate on precise digital instructions. This advancement has elevated production quality, reduced errors, and minimized waste.

Precision and Repeatability

The heart of CNC Routing Services lies in their unmatched precision. Whether it’s cutting intricate designs into wood, shaping composite panels, or creating custom parts, the results are consistent—every time. This makes the process indispensable for industries where tolerances are tight and accuracy is non-negotiable.

Industries Benefiting from CNC Routing Services

Woodworking and Furniture Manufacturing

Wood remains one of the most common materials routed using CNC technology. From decorative panels to complex furniture designs, CNC Router Cutting Experts bring efficiency and craftsmanship together, ensuring smooth edges, accurate curves, and flawless finishes.

Aerospace and Automotive Applications

Both aerospace and automotive industries demand reliability. Custom parts, lightweight structures, and prototype models often require the precision that Industrial CNC Routing Solutions provide. High-performance materials like composites and aluminum are routinely shaped with accuracy and durability in mind.

Signage and Branding

The signage industry thrives on customization. With Custom CNC Routing Services, businesses can create intricate designs, 3D lettering, and branded materials with unparalleled detail, giving companies the visual edge they need.

Key Advantages of CNC Routing Services

Superior Accuracy

One of the main reasons businesses turn to CNC Routing Services is their ability to achieve exact dimensions. Projects that require multiple identical pieces benefit tremendously from this precision.

Time and Cost Efficiency

Compared to manual labor, CNC routing significantly reduces production time. A single program can be replicated across countless parts, making it a highly cost-effective solution for both small and large runs.

Material Versatility

Whether working with plastics, wood, metals, or composites, CNC Routing Company operations are flexible enough to handle various materials while maintaining the same level of precision.

Scalability

From single prototypes to thousands of units, Industrial CNC Routing Solutions scale to meet project demands without compromising on quality.

Why Partner with CNC Router Cutting Experts?

The success of any CNC project depends largely on the team behind the machines. By collaborating with seasoned CNC Router Cutting Experts, businesses ensure that their designs are not only executed flawlessly but also optimized for efficiency. Professionals can recommend the best materials, suggest design adjustments, and ensure that every detail aligns with the intended outcome.

Custom CNC Routing Services: Tailored to Your Needs

Every business has unique requirements, and that’s where Custom CNC Routing Services come in. Whether you need one-off prototypes, decorative panels, or industrial components, customization ensures the final product meets exact specifications. These services offer flexibility in size, shape, and finish, catering to projects across diverse industries.

The Role of Industrial CNC Routing Solutions in Modern Manufacturing

Enhancing Production Efficiency

Factories today operate under strict timelines, and any delay can lead to significant losses. Industrial CNC Routing Solutions allow companies to meet deadlines with ease, producing parts quickly while maintaining precision.

Reducing Waste and Costs

By following exact digital blueprints, CNC routing minimizes material waste. This not only lowers costs but also makes the process environmentally responsible.

Driving Innovation

As industries innovate, the demand for custom components continues to rise. CNC routing empowers businesses to bring creative ideas to life without compromising on accuracy or scalability.

CNC Routing Services vs. Traditional Methods

Speed and Automation

Manual routing depends on human skill, which can be inconsistent. CNC Routing Services, on the other hand, automate the process, delivering faster results and higher quality.

Complexity of Designs

Traditional routing struggles with intricate or repetitive patterns. CNC machines execute complex designs effortlessly, opening up creative possibilities across industries.

Long-Term Reliability

With digital instructions at the core, CNC Routing Company processes ensure repeatability. Each piece matches the previous one, making it ideal for industries requiring standardized outputs.

Choosing the Right CNC Routing Company

Experience and Expertise

Not all providers are equal. Partnering with a CNC Routing Company that has years of experience ensures better results, especially for projects with strict tolerances.

Technology and Equipment

The latest CNC routers come equipped with advanced capabilities. Businesses should select providers that invest in cutting-edge equipment for optimal outcomes.

Customization Options

When flexibility is a priority, working with a provider offering Custom CNC Routing Services ensures projects are tailored to unique specifications.

Future of CNC Routing Services

As technology continues to advance, CNC Routing Services are expected to evolve with smarter automation, AI-driven programming, and even greater precision. These innovations will empower industries to push the limits of design, reduce costs further, and achieve levels of efficiency previously unimaginable.

The integration of robotics and real-time monitoring will also enhance scalability, making Industrial CNC Routing Solutions the backbone of next-generation manufacturing.

Why Businesses Trust Experts Like Xc Machining

While there are many providers, businesses look for reliability, consistency, and innovation. That’s why brands like Xc Machining continue to earn the trust of clients across industries. With a combination of advanced equipment, expert knowledge, and a customer-focused approach, they embody the true potential of modern routing technology.

Conclusion: The Value of CNC Routing Services

From woodworking to aerospace, from signage to automotive, the versatility of CNC Routing Services has made them indispensable to modern industries. With the ability to deliver precision, scalability, and customization, these services are a driving force in manufacturing innovation.

By partnering with trusted CNC Router Cutting Experts and leveraging the power of Industrial CNC Routing Solutions, businesses can ensure their projects are completed on time, within budget, and with flawless execution. Whether you require prototypes, custom designs, or large-scale production, Custom CNC Routing Services provide the flexibility and precision you need.

For companies looking to stay ahead in a competitive marketplace, investing in the expertise of a proven CNC Routing Company is not just an option—it’s a necessity.